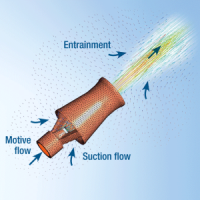

Liquid jet mixing nozzle provide an effective way to mix liquids in open or enclosed tanks. They produce an intimate mixing action between the components of a liquid, while keeping the contents of the tank in constant motion. In many cases they produce a mixing action that cannot be duplicated using mechanical methods. Liquid jet mixing nozzle can handle a variety of viscosities and types of liquids, including slurries and suspensions. Their thorough mixing action makes them especially useful for maintaining uniform liquid characteristics throughout the tank contents, such as temperature, pH, or solids distribution. Liquid jet mixing nozzle is also used to prevent separation of non-mixable liquids or stratification of liquids having different specific gravities. Liquid jet mixing nozzle offer low initial cost, light weight and easy installation. They are inherently non-clogging and with no moving parts, require little or no maintenance.

Liquid jet mixing nozzle allow the use of a smaller recirculating pump than normally would be needed to move a given volume of liquid. This saves energy while providing more effective mixing and circulation.

The main objective in oil refining is to convert a wide variety of crude oils into valuable final products such as gasoline, jet fuel and diesel. This final products produced by blending of multi component in final tanks.

In order to increase the production of final products, mixing time should be reduced as much as possible. So the mixing or blending time is very important in the refineries or such industry. The aim of this technology is to design customised tank mixing system solutions for each specific tank with mixing nozzle.